Punching is a metal forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. Punching is often the most cost effective method for creating holes in sheet metal in medium to high production volumes. When a special shaped punch is used to create multiple parts from a sheet of material the process is known as blanking.

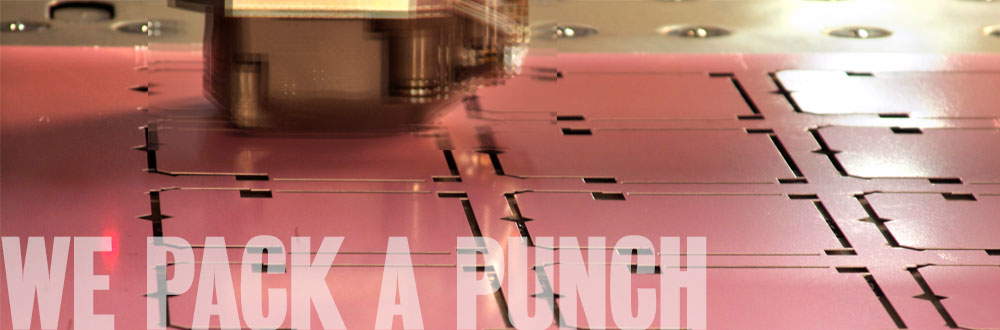

Brydenscot utilizes two different technologies or types of punching machines. The first type, the turret style punch, which has been around for decades and has proven to be the standard for processing sheet metal. The second type, a Trumpf single head hydraulic punch, which has tools that can be set up off-line while the machine is running. The tools sit on the motion rail for quick change, every tool on the rail can be rotated in the punch head, and the working speeds are 2x conventional turret punches. Add automated sheet loading and unloading and we have a combination that can give our customers the best quality and a competitive price.

F = 0.7tL(UTS)

The punch force required to cut metal